Self dumping bin

Self dumping bin for general muck, rubble and waste removal

The A-D model is our most requested automatic discharge bucket for cranes on the market. Its distinctive feature is the absence of the need for manual intervention during discharge, thanks to the innovative tipping mechanism activated by a bale arm, which houses two practical side ‘lock-unlock’ systems.

The discharge process is very intuitive: simply rotate the lifting arm backward and then pull it upwards to easily tip the bucket and allow material discharge.

Subsequently, the reverse operation returns the bucket to a horizontal position, ready to be safely lifted and refilled. This bucket is designed to facilitate the handling of a wide range of construction materials, including sand, gravel, debris, waste, and much more.

To meet various market needs, we offer the A-D model also in galvanized and aluminum versions, ensuring maximum strength, versatility, and durability in various conditions and work contexts.

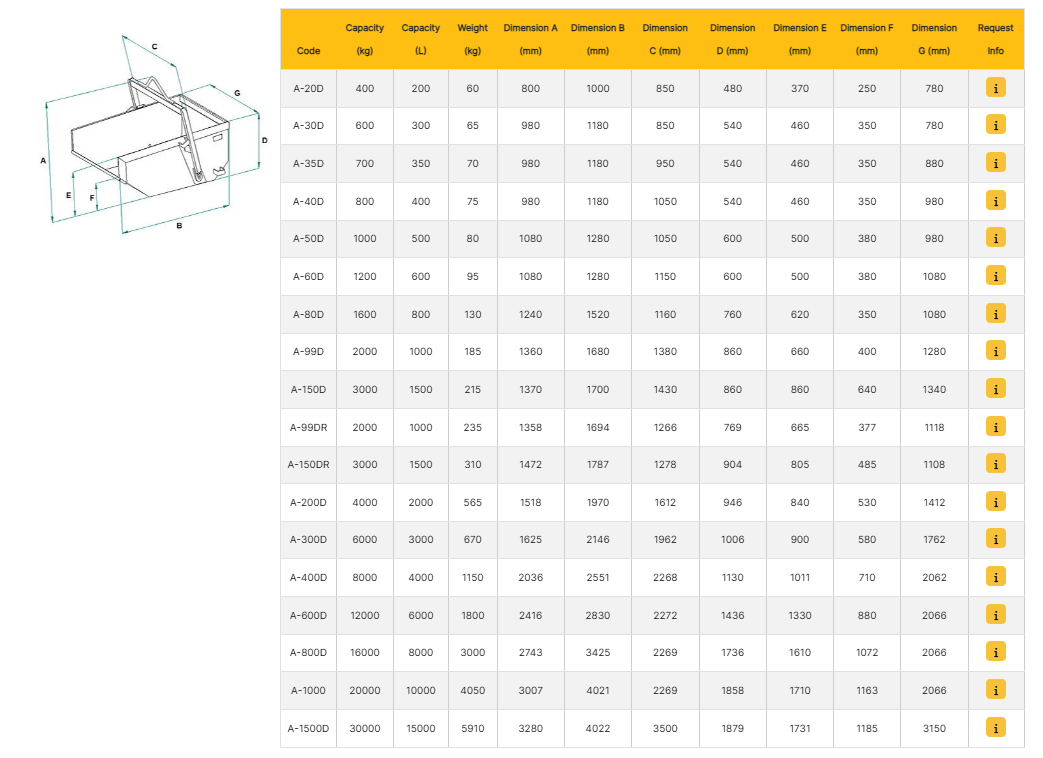

The range of available sizes is extremely wide, from 200 liters to 15,000 liters, allowing a precise choice based on your project’s specific needs.

Some features:

✅Versatility of use: The A-D bucket is extremely versatile and can be used for a wide range of materials, including sand, gravel, demolition debris, rubble, soil, and much more.

✅Safety: Thanks to its automatic discharge design, this bucket minimizes the risk of accidents due to manual intervention in the discharge area, greatly improving workplace safety.

✅Durability and strength: Made with high-quality materials and produced according to strict manufacturing standards, the A-D bucket is designed to withstand wear, impacts, and continuous stress.

✅Ease of use: The intuitive design allows for easy use, even for less experienced operators. The side lock-unlock system is also easy to manage.

✅Wide range of sizes: Available from 200 liters to 15,000 liters, this bucket can be adapted to various crane sizes and material handling requirements.

✅Environmental adaptability: The galvanized version offers greater resistance to corrosion, making the A-D bucket suitable for more challenging environmental conditions. Meanwhile, the aluminum model, due to its light weight, allows maximum crane capacity utilization up to the tip.

✅Maintenance: The design of this bucket model makes maintenance virtually non-existent, leading to greater efficiency and reduced overall operational costs.

✅Safety standards: In addition to manufacturing standards, this bucket meets stringent safety regulations, helping ensure operator protection and compliance with local and international regulations.

✅Customization: Custom modifications can be requested to adapt the bucket to the specific needs of your site.

Efficiency and productivity: Using this bucket can greatly increase efficiency and productivity in your material handling projects on site.

All buckets are designed, built, and subjected to rigorous quality tests in compliance with UNI EN ISO 12100, UNI EN 13854, ISO 8686, UNI EN 10027, and UNI EN 10204 standards. Each unit is equipped with a metal ID plate, a certificate of conformity, and a complete instruction manual for optimal use and maintenance.

We are also proud to offer a one-year warranty on our products, in accordance with European directives, ensuring your long-term peace of mind and satisfaction.

Contact Casey Group today for more details or a customized solution!